The brake master cylinder (BMC) is a critical component in your vehicle's braking system, requiring regular maintenance due to wear, contamination, or moisture intrusion. Replace faulty components promptly for optimal performance and passenger safety. Before replacing a BMC seal, ensure proper tools, ventilation, and safety precautions, consulting the repair manual. This process involves bleeding the brake system, disconnecting/reconnecting lines, inspecting internal parts, installing a new seal, and re-bleeding the system to prevent leaks. Regular maintenance, including seal replacements, supports high-performance upgrades for enhanced vehicle control and safety.

Looking to upgrade your vehicle’s safety? Learn how to replace your brake master cylinder seal with our comprehensive guide. Understanding the critical role of the brake master cylinder—it controls your car’s braking power—is step one. We’ll then walk you through common issues, essential preparation tips for maximum safety, and a detailed, easy-to-follow process for installing a new seal. By following these steps, you’ll ensure your vehicle’s brakes remain robust and reliable.

- Understanding the Brake Master Cylinder: Its Role and Common Issues

- Preparation and Safety Measures for Replacement

- Step-by-Step Guide to Installing a New Seal

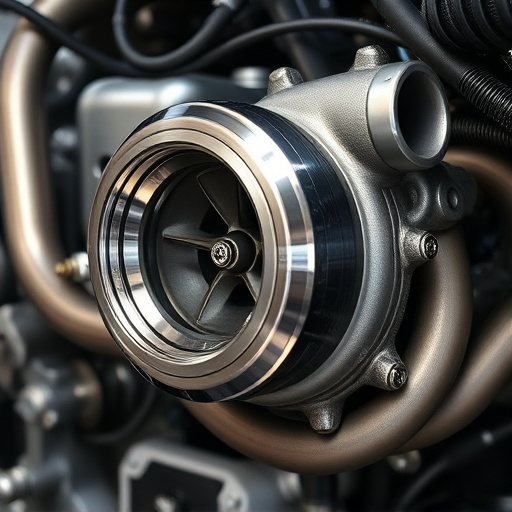

Understanding the Brake Master Cylinder: Its Role and Common Issues

The brake master cylinder (BMC) is a critical component in your vehicle’s braking system. It acts as the main source of hydraulic pressure, delivering power to the brakes when you press the pedal. By functioning as a pump, it ensures each wheel receives the necessary force to slow or stop the vehicle. Understanding its role is essential for recognizing common issues that may arise.

Over time, various factors can contribute to problems with the BMC. These include wear and tear on internal parts, especially seals and pistons, leading to leaks. Contaminants like dirt or debris entering through worn-out gaskets or cracks can also cause malfunction. Even moisture intrusion via the brake fluid can result in air bubbles, reducing braking efficiency. Recognizing these issues is crucial as neglecting them may compromise safety, making timely replacement of faulty brake master cylinder intake components necessary to maintain optimal vehicle performance and passenger security.

Preparation and Safety Measures for Replacement

Before tackling a brake master cylinder seal replacement, it’s crucial to prepare and prioritize safety. This involves gathering the necessary tools and parts, ensuring proper ventilation in your work area, and parking your vehicle on a level surface with the wheel chocks engaged for stability. Put on protective gear, including gloves and safety glasses, to shield yourself from any debris or potential hazards during the process. Additionally, it’s essential to consult your vehicle’s repair manual for specific instructions tailored to your make and model.

Remember that the brake master cylinder is a vital component in your car’s braking system, so proper handling is critical. Disabling this system even temporarily can lead to serious safety risks on the road. Take your time, double-check each step, and if you encounter any unfamiliar procedures or components, don’t hesitate to seek guidance from a qualified mechanic. This meticulous approach ensures not only effective brake master cylinder seal replacement but also reinforces the overall safety of your vehicle.

Step-by-Step Guide to Installing a New Seal

Replaceing your brake master cylinder seal is a crucial maintenance task for any car owner. Here’s a step-by-step guide to help you through the process, ensuring a safe and effective brake system. First, gather all necessary tools, including the new seal, a hydraulic fluid dispenser, and any specialized brackets or tools required for your specific vehicle model. Begin by bleeding the brake system to remove any residual air, creating a vacuum that aids in sealing. Next, carefully disconnect the master cylinder from the brake lines, securing them with clamps or braiding to prevent leakage. With the old seal removed, inspect the cylinder for damage and ensure its internal components are clean. Once ready, install the new seal, ensuring it’s properly seated and aligned. Reattach the master cylinder to the brake lines, re-bleed the system, and check for any leaks. Regularly replacing worn brake components, including your master cylinder seal, is key in maintaining optimal vehicle performance and safety, complementing even high-performance modifications like cold air intakes or cat-back exhaust systems.

Replacing the seal in your brake master cylinder is a crucial task that can significantly improve your vehicle’s braking performance. By following this guide, you’ve gained valuable knowledge on identifying common issues and the necessary safety precautions. Now, with a step-by-step approach, you’re equipped to install a new seal effectively. Remember, regular maintenance of critical components like the brake master cylinder is essential for ensuring safe and reliable driving.