The brake master cylinder (BMC) is a critical component ensuring safe braking. Regular maintenance, including checks on fluid, seals, and mechanical parts, prevents malfunctions. Early signs of BMC issues include soft pedal response, noise during deceleration, or mushy pedal feel. Structured diagnostics involving visual inspections, fluid level checks, pressure gauges, OBD-II scanning, and exhaust system exams accurately identify BMC problems, ensuring vehicle safety.

Diagnosing issues with your vehicle’s brake master cylinder is crucial for maintaining safety on the road. This component plays a vital role in ensuring smooth braking power. In this article, we’ll guide you through understanding the functions of the brake master cylinder, recognizing common symptoms of malfunction, and providing effective diagnosis techniques to troubleshoot problems promptly. By mastering these steps, you’ll be able to identify and address issues with your vehicle’s critical braking system efficiently.

- Understanding Brake Master Cylinder Functions

- Common Symptoms of Master Cylinder Malfunction

- Troubleshooting and Effective Diagnosis Techniques

Understanding Brake Master Cylinder Functions

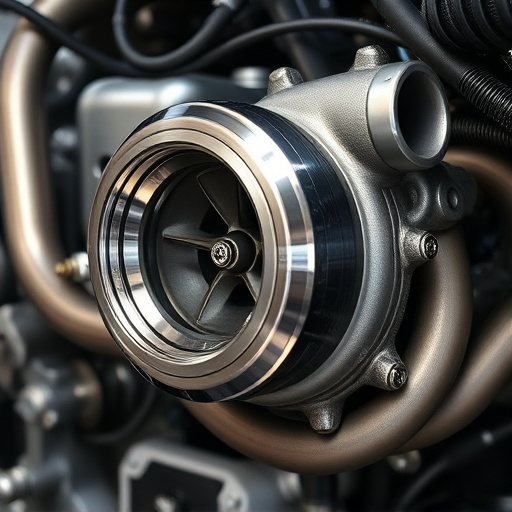

The brake master cylinder is a critical component of your vehicle’s braking system. It plays a pivotal role in translating the driver’s actions at the pedal into force that presses against the brake pads, ultimately slowing or stopping the vehicle. This mechanical lever multiplies the force applied by the driver, ensuring effective and safe braking even under high stress conditions. Understanding its functions is essential for recognizing potential issues early on.

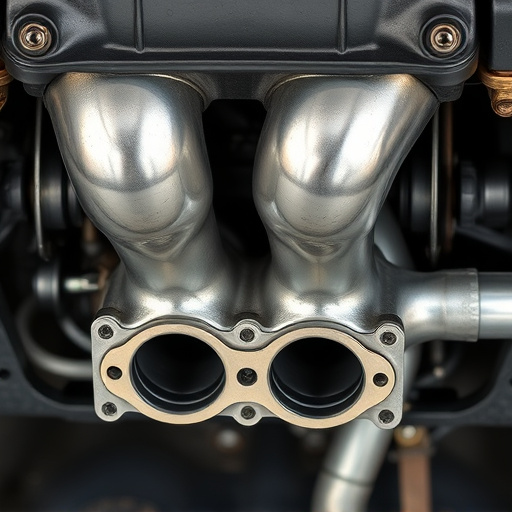

The master cylinder operates through a hydraulic system, where fluid pressure is generated to actuate the brakes. Issues can arise if the fluid becomes contaminated or leaks, leading to reduced pressure and subpar braking performance. Factors like worn-out seals, damaged cylinders, or compromised fluid quality all contribute to its malfunction. To maintain optimal vehicle control and safety, regular checks on the master cylinder and associated components—including performance air filters and suspension parts—are crucial. Additionally, ensuring proper maintenance of the performance exhaust system can also indirectly impact braking efficiency by maintaining overall vehicle health.

Common Symptoms of Master Cylinder Malfunction

The brake master cylinder is a critical component of any vehicle’s braking system, and its malfunction can lead to severe safety hazards. Some common symptoms indicate that your brake master cylinder might be the source of trouble. One of the earliest signs is a soft or spongy brake pedal. When you apply pressure, it feels irregular, almost as if there’s an air pocket in the line. This could be caused by low hydraulic fluid levels, air intrusion, or damage to the cylinder itself.

Another telling sign is a grinding or squealing noise coming from the brakes when you slow down. Unlike the familiar chirping of worn-out brake pads, this sound often comes and goes and isn’t always present. It’s more pronounced when braking hard or after a sudden stop. If the pedal feels mushy or sinks to the floor without fully engaging the brakes, it could suggest a severe issue with the master cylinder or even damage to the brake rotors. Regular maintenance, including checking fluid levels and replacing air filter kits, can help prevent these problems, but if your vehicle exhibits any of these symptoms, prompt inspection by a professional mechanic is crucial for safe driving.

Troubleshooting and Effective Diagnosis Techniques

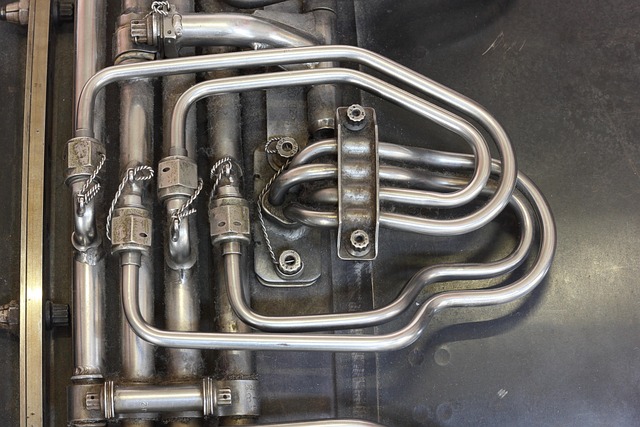

When troubleshooting brake master cylinder issues, it’s essential to employ a systematic approach that combines both standard and advanced diagnosis techniques. Start by visually inspecting the cylinder for any signs of damage, leaks, or corrosion. Check the brake fluid levels, as low fluid can indicate problems with the master cylinder or its components. If the fluid is discolored, it could suggest contamination or wear inside the cylinder.

Next, use diagnostic tools like a pressure gauge to measure braking pressure and check for any inconsistencies or losses. These issues might point towards problems with the cylinder’s internal mechanisms, such as contaminated or worn-out seals, pistons, or valves. Advanced techniques include scanning for trouble codes using an OBD-II scanner, which can provide insights into electronic components controlling the brake system, including the master cylinder. Additionally, examining the vehicle’s exhaust systems, specifically cat back exhausts, for unusual noises or performance issues could indirectly suggest problems with the braking system as a whole.

Understanding the intricacies of your vehicle’s braking system, especially the crucial role played by the brake master cylinder, is essential for effective diagnosis and maintenance. By recognizing common symptoms like reduced brake performance or abnormal noises, you can proactively address issues before they escalate. Employing systematic troubleshooting techniques, including visual inspections, fluid checks, and pressure testing, allows for accurate identification of master cylinder problems. Armed with this knowledge, you’ll be well-equipped to ensure your vehicle’s safety and stability on the road by promptly addressing any brake master cylinder concerns.