Inspecting a brake master cylinder involves checking its structure (piston, cylinder body, seals) for damage, corrosion, leaks, and wear. Conduct performance tests for leaks, air filters, and braking efficiency. Ensure smooth operation and optimal vehicle performance by verifying pressure maintenance throughout the stroke. Regular checks guarantee reliable braking and well-maintained components.

Before purchasing a new or used vehicle, inspecting the brake master cylinder (BMC) is crucial. This component plays a vital role in your safety by controlling braking power. In this guide, we’ll walk you through the essentials of brake master cylinder basics, key components to evaluate, and how to test for leaks and performance. By following these steps, you can ensure a well-functioning braking system and enhance your driving experience.

- Understanding Brake Master Cylinder Basics

- Evaluating Key Components and Their Condition

- Testing for Leaks and Performance

Understanding Brake Master Cylinder Basics

The brake master cylinder is a crucial component in your vehicle’s braking system, playing a central role in slowing or stopping your car. It works by generating pressure in the hydraulic lines, which then activates the brakes at each wheel. Understanding its basics is essential when inspecting it before purchase, as this knowledge allows you to assess its condition and functionality.

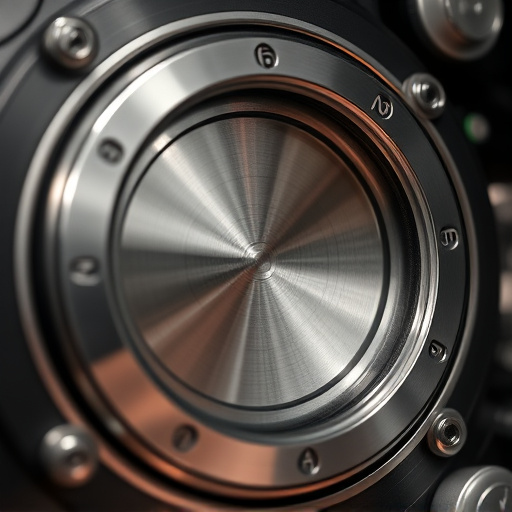

This cylinder acts as the brain of your vehicle’s braking mechanism, converting the force you apply on the pedal into hydraulic pressure. It consists of a piston, a cylinder body, and various seals and components that work together to maintain efficient brake performance. By checking for signs of leaks, corrosion, or damage, you can gauge whether it needs replacement and ensure that the new master cylinder functions seamlessly with your vehicle’s other suspension components, ultimately contributing to optimal vehicle performance.

Evaluating Key Components and Their Condition

When inspecting a brake master cylinder, one must delve into its key components and assess their condition meticulously. The primary parts to focus on include the cylinder itself, the piston, and the seal. These elements play a crucial role in ensuring optimal vehicle performance and safe braking. The cylinder should be free from any visible damage, corrosion, or leaks. Inspect the piston for wear, debris, or damage, as issues here can compromise the efficiency of the braking system. Similarly, check the seal for cracks or signs of degradation, as worn-out seals can lead to fluid leaks and reduced brake performance.

Additionally, consider evaluating the overall cleanliness of these components. A dirty master cylinder might indicate poor maintenance or contamination, which could negatively impact vehicle brakes. Checking for the condition of performance air filters is also beneficial, as clean filters enhance engine efficiency, thus positively influencing overall vehicle performance. Ensure that each component is in good shape and functions as expected before considering purchasing a brake master cylinder to guarantee safe and reliable braking.

Testing for Leaks and Performance

Before purchasing a new or used brake master cylinder, it’s crucial to test for leaks and assess its performance. Start by visually inspecting the cylinder for any signs of damage, corrosion, or oil seepage around the seals and connections. A simple way to check for leaks is to bleed the brakes while observing if there are any bubbles in the fluid or if it leaks out at any point. This step is essential as a leaky brake master cylinder can lead to reduced braking performance and even cause accidents.

Next, ensure the cylinder operates smoothly and efficiently. With the vehicle on level ground, pump the brakes several times to see if there’s any lag or resistance. Check that the pedal feels firm yet responsive. Additionally, verify that the master cylinder maintains its pressure throughout the entire stroke. Poor performance could indicate issues with internal components, necessitating further inspection or replacement. This process ensures you’re getting a reliable brake master cylinder that contributes to optimal braking efficiency, alongside well-maintained brake rotors and performance exhaust tips.

When inspecting a brake master cylinder, understanding its basic components and their condition is key. Evaluating each part thoroughly and testing for any leaks or performance issues will ensure you make an informed decision. By following these steps, you can confidently assess whether a brake master cylinder is in good working order before purchasing, safeguarding both your wallet and your safety on the road.